KS-WB3035-CNC Three Rolls Plate Bending Machine

The machine is mainly used for the roll bending processing of aluminum composite panel, pure aluminum plate, stainless steel board and steel bar. The NC machine thoroughly solves the problems of only driving the upper roller, and the difficulty of rolling thinner stave and can realize greater declivity of the upper roller and side roller through the change of roller and then roll conical barrel with huger coning; it is with clear operation interface and simple and convenient but precise operation. Therefore, it is one kind of product which can make you obtain high production efficiency, reliability and competitiveness.

Three-roller numerical controlled machine is the most innovative machine in the market at present, and it is especially suitable for the heavy loading work of rolling thickness bar. Very thick plate can be rolled only by increasing the distance between the lower side rollers. The fact has proved that straightway shorter than any others produced by any three-roller rolling machine can be obtained through numerical control software produced by our company in pre-bending of flexible shaft. It possesses many advantages compared with other similar three-roller rolling machines.Any end of two lower side rollers can go up and down separately; it’s convenient to bend taper and ellipse shape. The oil cylinder controls the three rollers independently, the hydraulic motor drives gear box as three rollers linkage, and the top roller will adjust the rotating speed to match the two lower rollers as per material thickness. It’s convenient to set the straight line of two ends, arc length, and radius by CNC control system.

Four-roller hydraulic numerical controlled rolling machine has the function of double-end pre-bending. It is the machine with the best performance in the international market; it has advantages not possessed by any other machine; the operator only needs determining the position of the side roller, and it will begin to make the fore-end pre-bending of bar material automatically with shortest straightway left; unlike single-side pre-bending rolling machine which needs the working procedures of sheet material moving out,U-turn, and re-feeding, etc, the four-roller hydraulic numerical controlled rolling machine can finish all the procedures only by passing once.Any end of two lower side rollers and bottom roller can go up and down separately; the bottom roller is below the top roller, the accuracy is very high, it can bend many different radius arc on one panel.The oil cylinder controls the three rollers independently, the hydraulic motor drives gear box as three rollers linkage, and the top roller will adjust the rotating speed to match the two lower rollers as per material thickness, the bottom roller is driven to rotate together with top roller. It’s convenient to set the straight line of two ends, arc length, and radius by CNC control system.

TECHNICAL PARAMETER

|

Model and parameter |

KS-WB3035

CNC Three Rolls Plate Bending Machine |

|

Maximum thickness of bending |

5-20 mm |

|

Maximum width of bending |

3000mm |

|

bending speed |

6m/Min |

|

Working mode |

NC, hydraulic drive |

|

Working voltage |

380VAC/50HZ |

|

Driving mode |

Oil cylinder independently control 3 rollers, hydraulic motor driven gearbox,3 rollers linkage moving. |

|

Power of main motor |

7.5kW |

|

4480x1120x1350mm | |

|

Bending function and shapes |

Any end of the two lower side rollers can go up and down freely so as to bend taper and ellipse. The three rollers are controlled by oil cylinder separately,hydraulic motor drives gear box for 3 roller linkage,the upper roller can automatically adjust rotating speed as per material thickness to match the speed of two lower side roller.Operator can set the straight line length,arc length and radius |

|

Weight of machine |

5200Kg |

|

Optional device |

Equipped with feed table, loading station and feeding device, it can become an automatic roll bending centre with high efficiency |

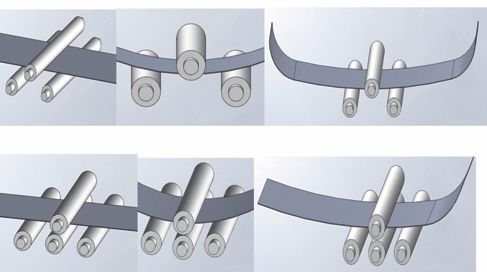

The processing schematic:

Pre:

KS-W1560S/W1560S-D--CNC heavy duty arc bending machine

Next:

KS-W3503--Manual Arc bending machine